When it comes to machining aluminum, selecting the appropriate tool is essential for achieving precision, efficiency, and a high-quality finish. Among the various types of cutting tools available, ball nose end mills frequently arise in discussions. But can ball nose end mills effectively handle aluminum machining? The answer is a resounding yes—with some important considerations. Let’s explore the capabilities, advantages, and best practices for using ball nose end mills in aluminum machining.

The Unique Strengths of Ball Nose End Mills

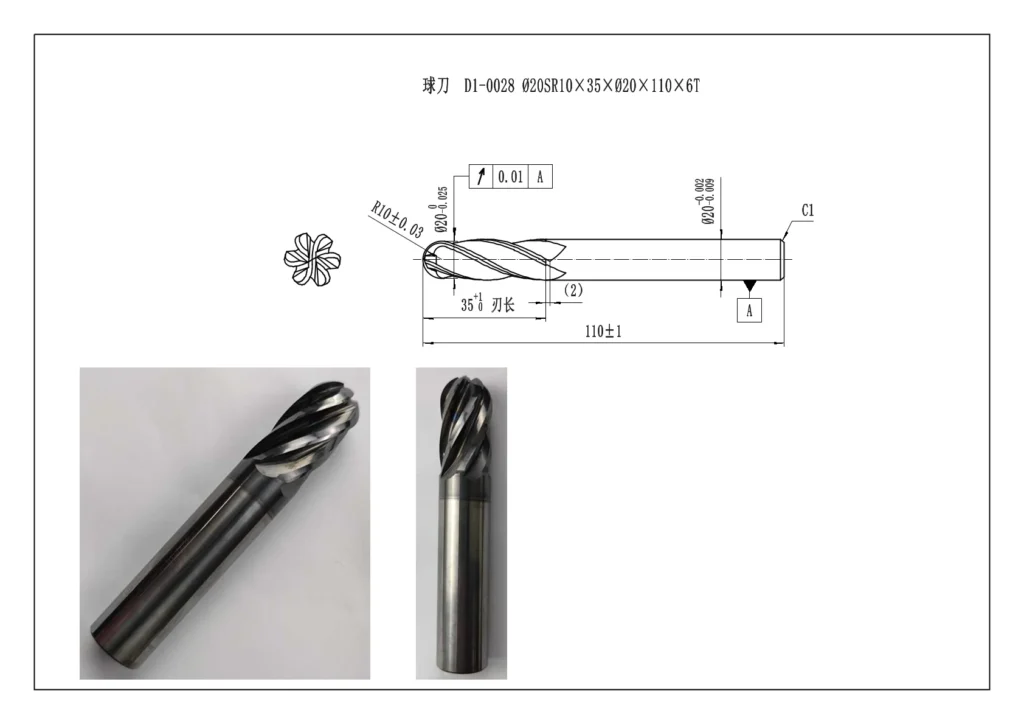

Ball nose end mills are characterized by their hemispherical cutting tips, making them ideal for 3D contouring, sculpting, and finishing operations. Unlike flat end mills, which are better suited for creating sharp edges and flat surfaces, ball nose end mills excel at producing smooth, curved surfaces. This capability makes them a popular choice in industries such as aerospace, automotive, and mold-making, where complex geometries are prevalent.

In aluminum machining, ball nose end mills offer several advantages:

Smooth Surface Finish: The rounded tip reduces the likelihood of visible tool marks, resulting in a superior surface finish.

Versatility: They can handle both roughing and finishing operations, making them a versatile tool in the machining process.

Reduced Chatter: The design of ball nose end mills helps minimize vibration, which is particularly beneficial when working with softer materials like aluminum.

Challenges in Aluminum Machining with Ball Nose End Mills

While ball nose end mills are highly effective, machining aluminum presents unique challenges that require careful tool selection and parameter optimization. Aluminum is a soft, non-ferrous metal known for its high machinability, but it also has a tendency to stick to cutting tools, leading to built-up edge (BUE) and poor surface finishes. Additionally, aluminum’s low melting point means that excessive heat can cause workpiece deformation or tool wear.

To address these challenges, ball nose end mills designed for aluminum often feature specific characteristics:

Sharp Cutting Edges: Sharp edges reduce the risk of material adhesion and improve chip evacuation.

High Helix Angles: A high helix angle (typically 35° to 45°) helps lift chips away from the workpiece, preventing recutting and heat buildup.

Polished Flutes: Smooth, polished flutes reduce friction and improve chip flow, further minimizing the risk of BUE.

Optimizing Cutting Parameters for Aluminum

To get the most out of ball nose end mills in aluminum machining, it’s essential to optimize cutting parameters. Here are some key factors to consider:

Spindle Speed: Aluminum machining typically requires high spindle speeds (RPM) to achieve efficient material removal. For ball nose end mills, speeds between 10,000 and 20,000 RPM are common, depending on the tool diameter and machine capabilities.

Feed Rate: A higher feed rate helps prevent material from sticking to the tool. However, it’s important to balance speed with precision to avoid compromising surface finish.

Depth of Cut: Ball nose end mills can handle both shallow and moderate depths of cut. For roughing, a deeper cut may be used, while finishing operations typically require lighter passes to achieve a smooth surface.

Coolant Use: While aluminum machining can often be done dry, using a coolant or lubricant can help dissipate heat and improve chip evacuation, extending tool life and enhancing surface quality.

Tool Coatings and Materials

The performance of ball nose end mills in aluminum machining can be further enhanced through specialized coatings and materials. Uncoated tools are often preferred for aluminum because they provide sharp cutting edges and reduce the risk of material adhesion. However, some coatings, such as TiB2 (titanium diboride), are specifically designed for non-ferrous metals and can improve tool life and performance.

In terms of tool material, carbide is the most common choice for ball nose end mills due to its hardness, wear resistance, and ability to maintain sharp edges. High-speed steel (HSS) tools are less common but may be used for less demanding applications or when cost is a primary concern.

Applications in Aluminum Machining

Ball nose end mills are widely used in aluminum machining for a variety of applications, including:

3D Contouring: Creating complex shapes and curves in aerospace components or automotive parts.

Mold and Die Making: Producing intricate molds with smooth, polished surfaces.

Prototyping: Developing prototypes with detailed features and fine finishes.

Engraving and Decorative Work: Adding artistic or functional details to aluminum surfaces.

In these applications, the ability of ball nose end mills to produce high-quality finishes with minimal post-processing makes them a valuable tool in the machinist’s arsenal.

Best Practices for Using Ball Nose End Mills on Aluminum

To maximize the effectiveness of ball nose end mills in aluminum machining, follow these best practices:

Choose the Right Tool: Select a ball nose end mill with sharp edges, a high helix angle, and polished flutes.

Optimize Parameters: Adjust spindle speed, feed rate, and depth of cut to suit the specific requirements of your project.

Use Coolant When Needed: While not always necessary, coolant can improve performance in high-speed or high-volume machining.

Monitor Tool Wear: Regularly inspect the tool for signs of wear, such as chipping or dull edges, and replace it as needed to maintain quality.

Ensure Proper Chip Evacuation: Use compressed air or coolant to clear chips from the cutting area, preventing recutting and heat buildup.

From their ability to create smooth, complex geometries to their versatility in both roughing and finishing operations, ball nose end mills are a powerful tool for aluminum machining. By understanding their strengths, optimizing cutting parameters, and following best practices, machinists can achieve exceptional results while extending tool life and reducing costs. Whether you’re working on aerospace components, automotive parts, or intricate molds, ball nose end mills offer a reliable and efficient solution for your aluminum machining needs.

Changzhou Sailong Tool Factory was established in 2010 and is located in Changzhou City, Jiangsu Province. It is an enterprise focusing on the metal products industry. We manufacture and process a wide range of high-quality tools and machine parts for use in a variety of industries, including manufacturing, construction and automotive.

Our carbide tools, with their extraordinary wear resistance, high temperature resistance, corrosion resistance and excellent cutting performance, can still perform stably in extreme working environments, and their service life far exceeds that of similar products. Their unique alloy formula and precision manufacturing process ensure that every cutting is accurate and correct, greatly improving processing efficiency and finished product quality.